on september 18, 2015, the three-day beijing 2015 china international paper technology exhibition and conference came to an end in the new beijing agricultural exhibition hall. the exhibition is co sponsored by china paper association, china paper society and china pulp and paper research institute. the exhibition covers an area of 13000m2, covering pulp and paper machinery and equipment, spare parts, auxiliary equipment, automation equipment and instruments; all kinds of commercial pulp, paper and paperboard; waste paper and waste paper utilization technology, equipment, etc; paper chemicals; new technology and equipment for environmental protection and comprehensive utilization; special paper materials and equipment, etc.

early autumn is the most beautiful season in beijing. under the leadership of general manager han changsheng, golder technology went to beijing to participate in the 2015 beijing china international paper technology exhibition. as a military truck loaded with the company's products drove into the exhibition hall. colleagues in the exhibition are busy and busy with their work. they spend one day putting our products in the exhibition place safely.

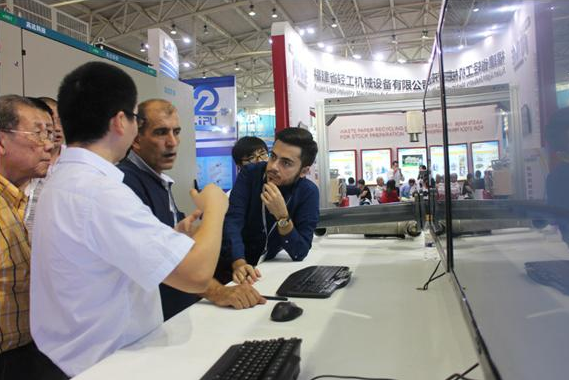

as a global partner of siemens in china's pulp and paper industry, we hope to tap the potential of siemens products, bring their performance to the full play and benefit china's pulp and paper industry. we have been adhering to the concept of advanced manufacturing with automation and information technology, and under the leadership of president han, we take "service" and "quality" as the focus of our work, which has won the unanimous praise of customers. so in this exhibition, we have received many of our old customers, old friends, but also a lot of new customers, including foreign friends.

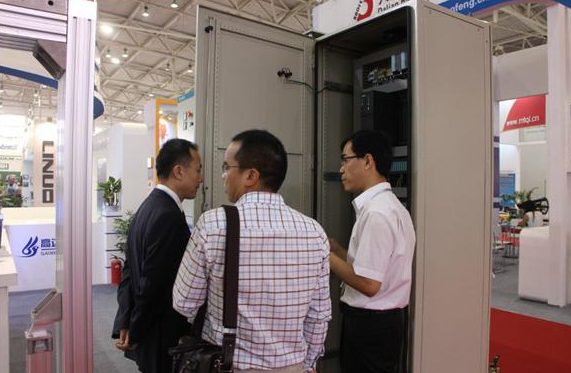

over the years, our company has been engaged in the automation control of pulp and paper industry, and has developed many products with independent intellectual property rights. for example, the rectifier unit launched in 2010 has successfully launched dozens of sets, so far it has been in stable operation on site. the m2 system composed of s120 inverter of siemens sinamics family and the m3 system composed of g120 are favored by more and more customers. among them, m3 system is cost-effective, and with our years of understanding and application experience of siemens products, the actual use effect is much higher than that of the same grade inverter.

our "multi wavelength infrared detection system" has just participated in the third civil military integration innovation competition of chinese academy of things, and has also attracted the attention of our customers. green qcs scanning frame, no longer like the previous need for radioactive sources, customers save trouble and cost, workers are safer. a customer came to our booth, and it happened that the sample paper for testing on our qcs scanning frame was produced by their company. he was very surprised by the results of the field test, and even wanted to order one on the spot, which made us very happy and moved.

we have reached the expected goal and felt the pressure of the market when we participated in the exhibition. in the case of overcapacity and higher environmental protection requirements, the test of paper industry is quite severe. so exhibitors and visitors to the exhibition have been shrinking. but we are also pleased to see that there are more professional visitors and more customers with demand. my biggest feeling is that pulp and paper industry in some emerging economies such as india, brazil, pakistan and so on is on the rise. at present, they pay great attention to the mechanical equipment related to pulp and paper making, and the attention to the automatic control system is relatively small. we think it is a process they must go through. first, the equipment can produce products, then the product rate and quality will be pursued. then advanced automation control will be sought to solve this series of problems. our company has been the leader of siemens' latest products in pulp and paper industry by the dcs automatic control system of siemens pcs7 platform. the program library specially developed by ourselves is used to dig into the potential of siemens plc, perfect and flexible functions, friendly human-machine interface and fault source, etc. which will bring great convenience to your use and maintenance.

under the leadership of president han, gaoda technology continues to move forward, and our product quality and service quality are continuously improving. our green qcs, reliable rectifier unit blm, high quality paper disease detection system mis, internet plus mes system and so on can help customers improve product quality and enhance their competitive strength effectively. congratulations on the success of this exhibition and wish our efforts to be recognized by more users.